1 (586) 285-8400

SECTIONAL rebuildS

PUT an end to lost production

Sectional rebuilding offers a cost-effective alternative to a complete rebuild or remanufactured machine. By targeting specific worn or damaged areas, ACG Direct can restore your multi-spindle screw machine to peak performance—fast.

Our expert technicians address only what’s needed to get your machines back online, running efficiently, and producing profit again. Every component is inspected, machined, and fitted with precision to ensure long-term reliability and accuracy.

-

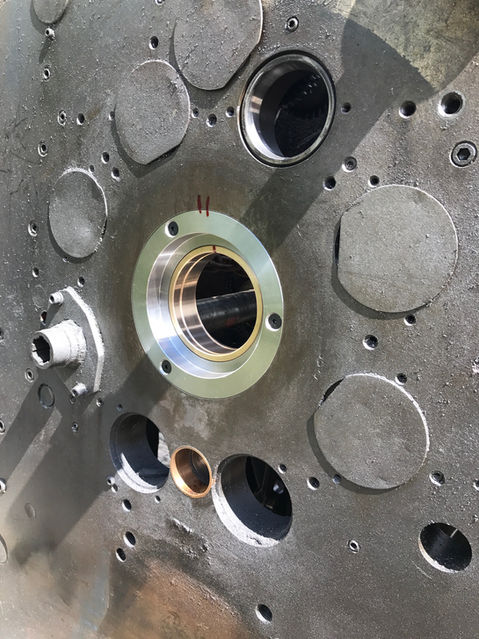

Carrier Rebuilding – Complete inspection and overhaul of major O.D.s, locking blocks, spindle bores, MTS stem, and pilot bore.

-

Back-End Chucking & Stock Feed Slide Rebuilds – Restore smooth, consistent material feeding and precise chucking performance.

-

Main Tool Slide Repair – Grind stem, re-sleeve, and restore to OEM alignment.

-

Geneva & Index Mechanism Service – Repair, reset, and calibrate for accurate indexing and cycle timing.

-

Slide Repair & Restoration – Ground to original height with in-house scraping and flaking for superior fit and finish.

-

Main Drum Shaft Repair – Precision repair of drum shaft bores, keyways, and taper pins to restore perfect fit, alignment, and indexing accuracy.

-

Clutch & Gearbox Overhaul – Complete teardown, inspection, and rebuild to restore dependable drive performance.