1 (586) 285-8400

ACG MES 1000: Visual Highlights

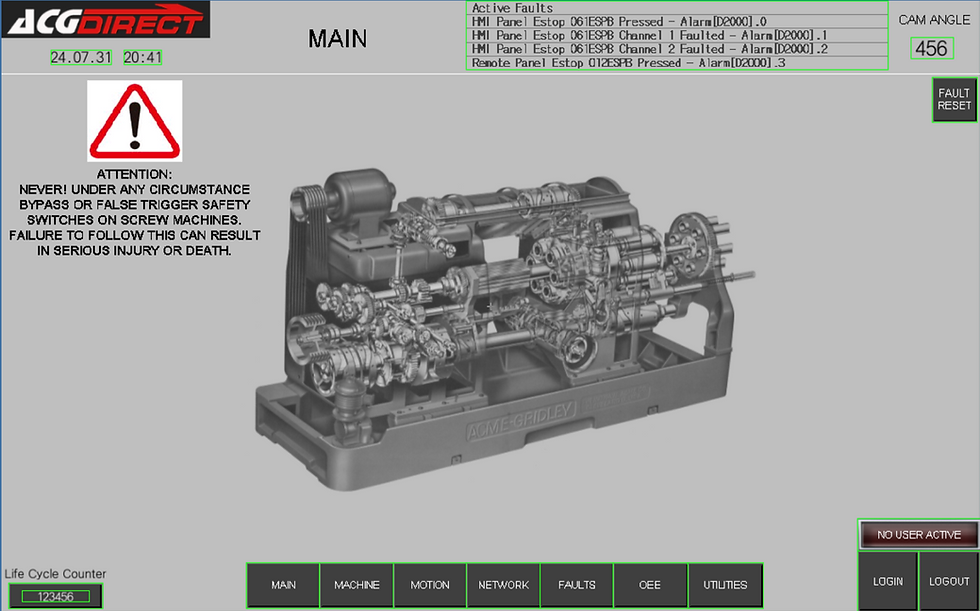

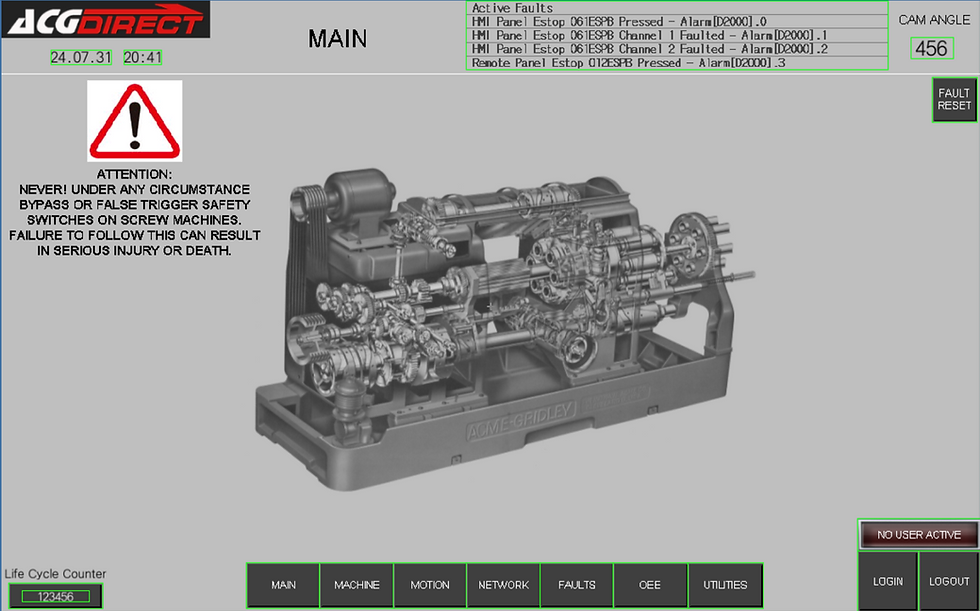

Upon startup, the home page is displayed, providing essential safety information to the user. Additionally, it shows real-time data, including the 'Cam Angle Degree,' current time and date, active faults, and fault reset options. This critical information is consistently available across all subsequent menus.

This menu provides setup options to add, edit, or delete active users from the system. Users can be configured to log in using either a password or badge ID. Additionally, permission levels can be assigned as follows: User Level Maintenance Level Supervisor Level The selected permission level determines the menus and functions accessible to each user, ensuring appropriate access based on their job role.

This menu displays all fault history in chronological order of occurrence. Users with appropriate permissions can select and delete fault records. Otherwise, the data is stored indefinitely for future reference.

Upon startup, the home page is displayed, providing essential safety information to the user. Additionally, it shows real-time data, including the 'Cam Angle Degree,' current time and date, active faults, and fault reset options. This critical information is consistently available across all subsequent menus.

FEATURES

System includes:

- Mitsubishi or Allen Bradley platform-based controls.

- Compact electronics with complete system integrated into main HMI.

- Full illumination of push button controls.

- Dual channel safety for all safety devices such as Crank Safety, Hand Chuck Safety, and Door Switches.

- Recipe driven inputs for all job specific data.

- Integrated employee card reader for login security and operator performance monitoring.

- Control of parts counters, edge counters, shift points, and chip conveyor control pulsation.

- Built in pick-off, threading, and stock depletion functionality.

- Added auxiliary inputs for other devices such as broken tool detection, in process gaging, loaders and more.

- Data acquisition with OEE information on screen or export capable.

ACG-MES1000 upgrade retrofit

Upgrade Your Screw Machines with Our State-of-the-Art Controller

Transform your machinery with our cutting-edge controller, designed for seamless integration. Replace outdated relay or PLC controls effortlessly and elevate your machine’s performance with our comprehensive solution.

Our user-friendly transition process ensures minimal downtime:

-

Remove the old control system.

-

Install our advanced controller using the straightforward wiring diagram provided.

-

Connect the encoder and power.

Experience a modernized, efficient operation with just a few simple steps. Upgrade today and enhance your machine’s capabilities with ease.